Industrial and Mechanical

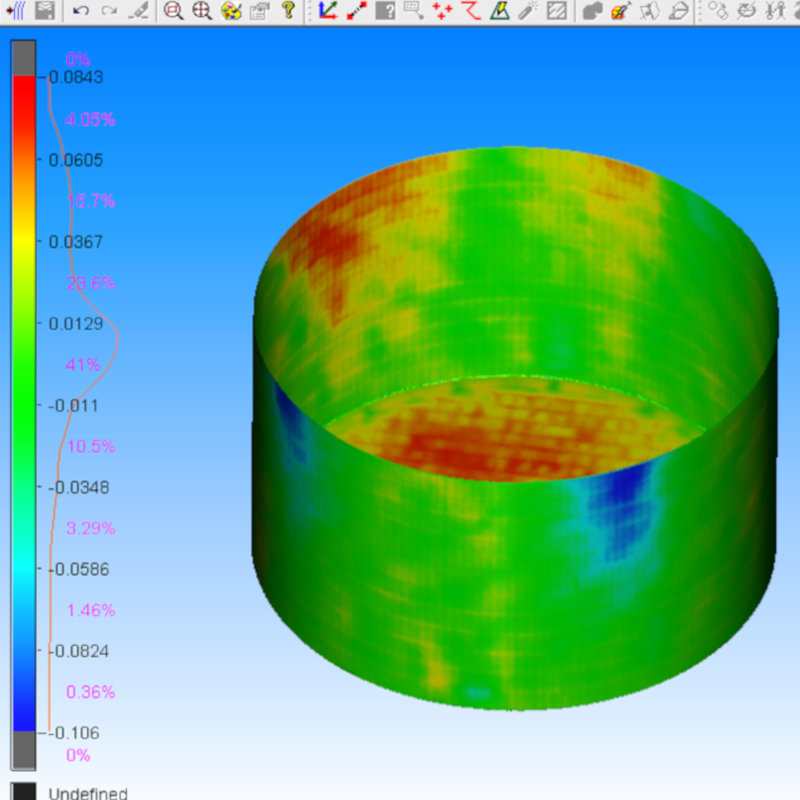

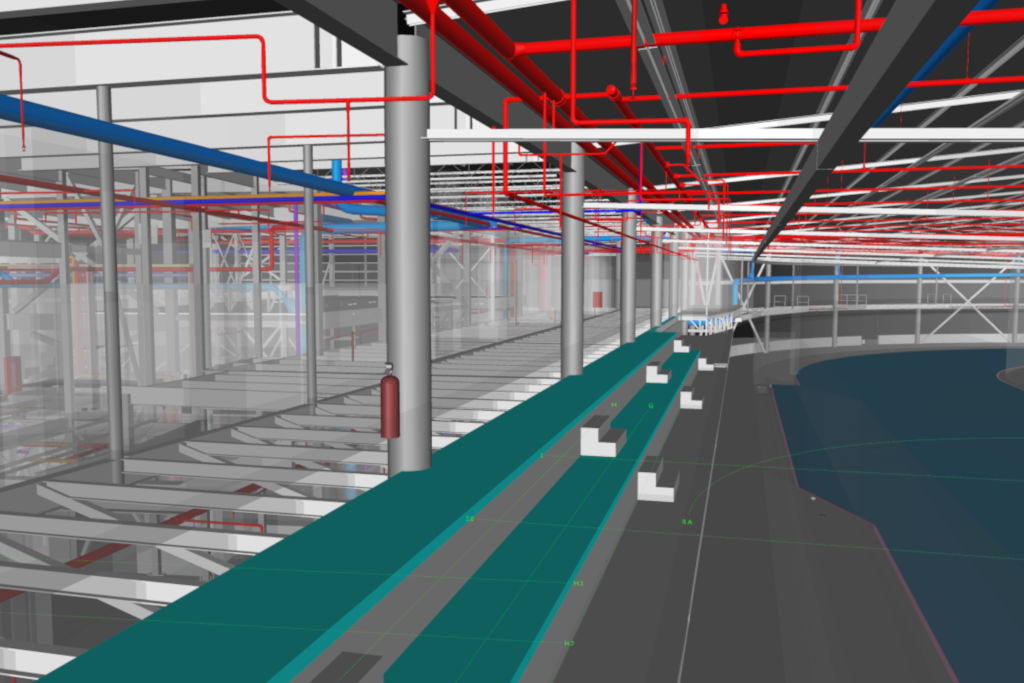

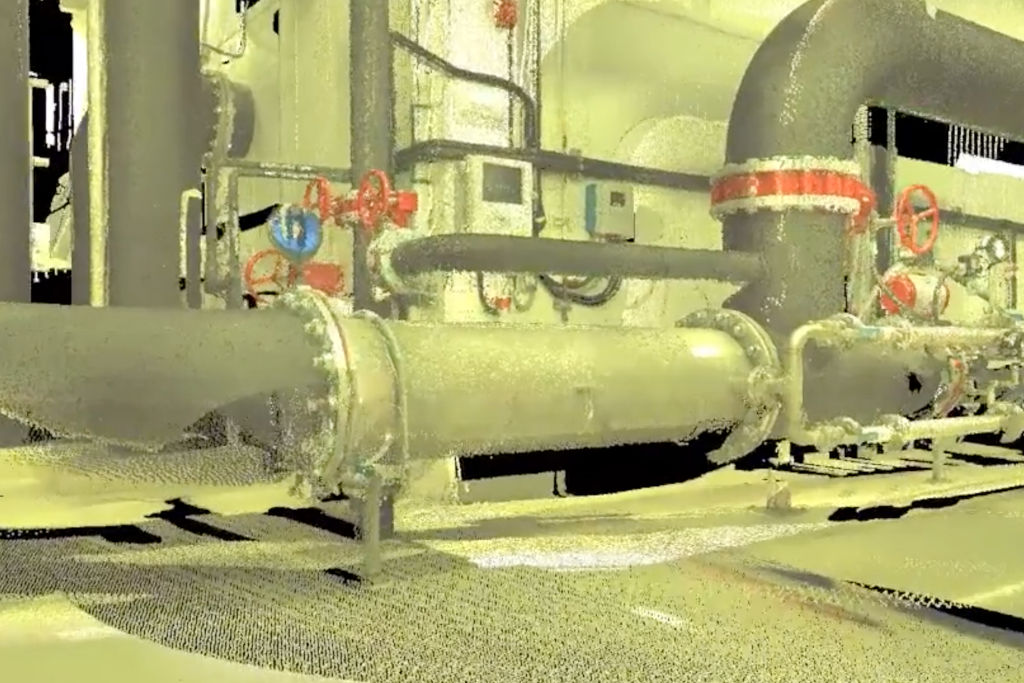

The requirements of the industrial sector are very high and the accuracy of measurements is essential. Géomog uses specialised scanners that produce point clouds and meshes of the highest precision to produce 3D models that meet the required specifications.

To ensure the quality of our work, we carry out quality checks using a combination of technology and a working method We have used this tool in numerous projects in refineries, mining facilities, water treatment plants, sorting centres, airport baggage conveyors, etc. 3D scanning also allows us to scan industrial equipment to determine the position of a new element or to facilitate the replacement and maintenance of existing elements, such as pipes, conveyors, pumps, ovens and structural elements.

The benefits of 3D scanning

- Time saving: 3D scanning reduces the need for professionals on site. In addition, after the point clouds are taken, several people can work with the same data to speed up the project.

- Easy data sharing: Thanks to 3D scanning, information is shared and validated more easily and quickly between the various project stakeholders.

- Accuracy: 3D scanning performs data collection that reduces the risk of errors. Point clouds offer an accuracy that cannot be achieved with traditional techniques.

- Security: Data from irregular and hard-to-reach areas can be easily and safely taken from a distance.

- Large-scale projects: 3D scanning is ideal for large-scale projects.